Quick question: can landfill bring dumped plastic into the circular economy?

The world produces 2billion tonnes of waste annually and landfill is nearing capacity. So can a new waste-to-energy approach help?

Fortunately, there are viable alternatives to traditional landfill operations, such as on-site conversion of plastics right at the sites themselves. This method reduces transportation costs and increases energy efficiency with minimal infrastructural changes. We turn to Stellar3 to explain the process and its impact.

How does the process of plastic conversion at landfill work?

The ability to convert mixed plastics at a landfill site needs to address three key issues: feedstock volume, plant size to transform. The municipal solid waste (MSW) arrives, with a minimum volume of 150tonnes per day. Then, if necessary, the desired mixed plastics are separated from the other wastes and processed through Stellar3’s thermochemical conversion system – plastics are shredded, washed, dried, then fed into a thermal unit that creates a mixture of syngas.

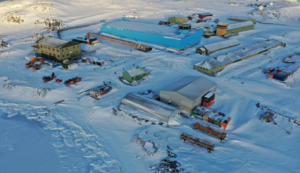

The gases are separated and cleaned to generate a set of desired outputs. One is to use the syngas for natural gas replacement and to generate electricity; another involves condensing the syngas into pyrolytic oils to make new plastics, chemicals or other petroleum-based products. The third is condensing and then distilling the resource into blend-ready fuels. Stellar3 plants are small enough — 350-500m2 depending on configuration – that they can be built adjacent to or on the landfill site.

Examples of pre-pyrolysis innovations include extracting chlorine from PVC and mixed plastics and drying wet waste with low energy. Even the most stringent off-take requirements can be met by our post-pyrolysis syngas management, cleanup, and hydrogenation. To address toxic mixed components in feedstock, gas-phase pollutants are oxidised, reducing to less than 10-16 parts per million, well below global emission standards. During project design, feedstock lab analysis ensures plant applications meet local requirements.

How long has this process been available?

As a viable, commercial solution for a variety of waste stream applications, thermochemical conversion is now just emerging as a circular and economically viable waste to energy solution.

Stellar3’s thermochemical conversion uses modular subsets of processes to convert longer chemical chains into shorter, gas-based chemical chains that can be managed to maximize desired output quality. After more than three years of laboratory, pilot and commercial-scale testing, and application adjustments, this solution has been available in its commercial form for approximately 12 months.

It uses a pyrolysis process to convert solid objects into liquids and then gases. The practice of pyrolysis dates back hundreds of years. Currently, pyrolysis modules have been applied to very specific waste streams with varying degrees of success, but most designs are considered uneconomical due to unreliable systems, inefficiencies, and low product quality.

Over the past three years, Stellar3’s thermal experts have applied solution engineering to the entire technology application, including pre-pyrolysis preparation and post-pyrolysis gas management. Examples of pre-pyrolysis innovations include extracting chlorine from PVC and mixed plastics and drying wet waste with low energy.

How widely used is the process?

The plants are just now being commercialised and are available to select partners. The first commercial plant will be commissioned in Africa in February 2024, with the next 10 plants delivered later in th — going online in October and November. By 2027, sales deliveries of plants are expected to reach 100.

Stellar3 will also pilot a new plant for ‘whole tire transformation’ in May 2024. In the current system, end-of-life tires are first shredded at large tire shredding facilities that require significant investment and energy to operate. The new preparatory module will reduce carbon emissions generated by tire shredding plants.

How resource heavy is the plastic conversion process?

Our thermochemical conversion process means 75% of the mixed plastic waste is converted into syngas, which is then condensed into a high quality, low sulphur oil. In addition, over 80% of the plant’s LPG gas and electrical needs are met by the remaining non-condensable syngas.

Combined with the ability to build smaller facilities where waste exists– at landfills, within communities, wherever the feedstock is readily available — this level of efficiency provides a foundation for rapid expansion of waste transformation facilities that minimise the environmental impact of waste worldwide through thermochemical conversion. Facilities addressing as little as 9,500 tons of mixed plastics annually will deliver approximately 8million blend-ready litres of fuel.

Are there any environmental advantages from the use of pyrolytic oil produced through landfill conversion, in terms of its end use, compared with traditional oils?

For waste-transformed oils and blend-ready fuels, CO2e emissions are a challenging and varying calculation based on the quality of waste collection, waste disposal methodology, as well as the set of plant locations and output distribution networks.

When converting plastic waste into blend-ready liquid fuels, one calculates CO2e savings that include oil extraction, shipment to the refinery, and final shipment to the location. Currently, nearly 100% of refined fuels are imported into countries like the Philippines and South Africa, where Stellar3 has projects in development. Data availability and changes regarding waste treatment and landfill operations will also alter certain CO2e calculations over time and be applied as available.

The entire carbon footprint associated with oil extraction, refinery processing and transport to point of use, may vary depending on: the final destination of product, type of output from thermochemical conversion, and relative location for the refinement of desired outputs – chemicals, fuels, plastics, electricity, and so forth. Approximately 12% of the energy required to create new plastic resin is consumed in the production of recycled resin for plastic manufacturing, according to the Association of Plastic Recyclers.

Unlike other pyrolysis or gasification providers in the marketplace today, Stellar3 will leverage neural networks, artificial intelligence, to develop proprietary machine learning [ML] models unique to this industry. In some cases, we will work with academic and commercial consultants to hypothesise and identify best operating procedures using a multi-layer analysis of data.

To begin with, ML efforts will study, organise, and improve feedstock and offtake logistics and supply chains. In order to improve efficiencies and output quality, multi-layer ML real-time predictive analysis will be implemented using cameras for spectral identification — visual and infrared — sensors, scientific instrumentation, temperature, pressure, chemical monitoring, and other available and identified data.

What can you tell us about the carbon equivalent emissions from the process?

Using actual production throughputs rather than extrapolating results based on pilot and lab experiments, CO2e savings will be calculated once facilities have been operating a full year.

- With localized plants, transportation savings are calculated based on shipping data, and some inland trucking is assumed. Using grams per kilometre tonne transportation savings, annual tonnage of waste is multiplied by a factor to calculate CO2e savings. Plastics to liquid fuels have a factor of .032, MSW to electricity has a factor of .02, medical waste has a factor of .06, large MSW has a factor of .015, and EOLT has a factor of .05.

- Output marginal costs vary widely, especially for developing countries where 90% or 100% of refined fuels are imported. The Stellar3 Mixed Plastics to Liquid Diesel plant offers substantial CO2e savings. One key goal in the Philippines, for example, is to eliminate all plastics being dumped into the ocean.

More quick questions:

Quick question: what policies should we prioritise to tackle plastic pollution?

Quick question: What does organisational sustainability look like in 2024?

Images: Collab Media (top) / Stellar3 (bottom)