Scotch whisky set for sustainable energy overhaul

A new £45million facility will deliver huge financial and carbon savings for Scotland’s premier luxury drinks market.

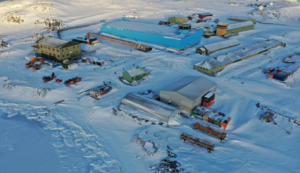

The AMP Clean Energy Project focuses on a Berrick-Upon-Tweed site, where new infrastructure running on electric and biomass will replace old fossil fuel boilers powering the Simpsons Malt Limited’s Tweed Valley Maltings headquarters.

A key ingredient in Scotch whisky, it is estimated that once online the development will cut around 25,000 tonnes of carbon each year. Equivalent to the entire annual output of 11,000 homes, emissions for the UK’s largest malting facility will plummet by 80% as a result. 2.5kg of malt is required to produce a single litre of whisky, so this process can offer 275g of carbon saving for every litre of whisky produced.

In addition to these savings, a so-called ‘reinvention’ of local, renewable biomass fuel into an energy storage mechanism also offers cashback to those invested in generation. In periods where there is no excess renewable power available, this new system can produce industrial heat through electrification.

The first time a high voltage electrical boiler has been powered by wind energy in the UK, the power used would otherwise have been lost due to ‘energy constraints’. With the National Grid unable to store energy at scale, or redirect to other locations, on days when there is an excess – for example, high winds – the only solution is to ask turbine operators to switch windmills off, a process that essentially costs consumers hundreds of millions each year. Construction work is expected to complete by next summer.

‘We are proud to be able to support Simpsons Malt Limited on their decarbonisation journey with this trailblazing low carbon project that will deliver large scale Scope 1 emission reductions. This initiative is so exciting because it uses local, low value biomass as a form of energy storage that can provide decarbonisation when the wind doesn’t blow,’ said Mark Tarry, CEO at AMP Clean Energy.

‘This is the first project of its kind in the UK and the first time a high-voltage electric boiler will decarbonise an industrial heat process. It could be replicated across other industries. This project will save consumers money and drive forward the broader energy transition towards a net zero future, he continued. ‘The project is also AMP’s largest single investment to date.’

More on energy:

https://environmentjournal.online/headlines/labours-green-prosperity-plan-fails-optimism/

https://environmentjournal.online/headlines/global-hydropower-capacity-five-year-leap/

https://environmentjournal.online/headlines/limit-energy-transition-materials-to-cut-human-and-environmental-cost/

Image: Simpsons Malt Limited