The University of Surrey’s innovative solution slashes the price of converting waste emissions into clean, synthetic fuel.

First publishing results in Applied Energy, the British-developed Dual-Function Material [DFM] process involve both carbon capture and conversion stages. According to the team responsible, this method could match or outperform more established systems already in place.

Under optimal conditions, DFM has now been shown to remove carbon at a cost of $740 per tonne. Not only is this significantly lower than the current average, there is also potential for the price to drop below $400 per tonne as material science improves.

‘For the first time, we’ve been able to demonstrate it can be financially competitive to use DFMs for direct air capture (DAC) – all the while creating clean fuel like methane in the process,’ said Dr Michael Short, Associate Professor of Process Systems Engineering at the University of Surrey.

‘Using green hydrogen from renewable electricity and carbon from the atmosphere, our system can help to replace fossil feedstocks in sectors like steel manufacturing,’ Short continued. ‘If a steel mill uses this fuel, it could effectively have zero net emissions – offering a sustainable path to decarbonise industries that are otherwise hard to electrify.’

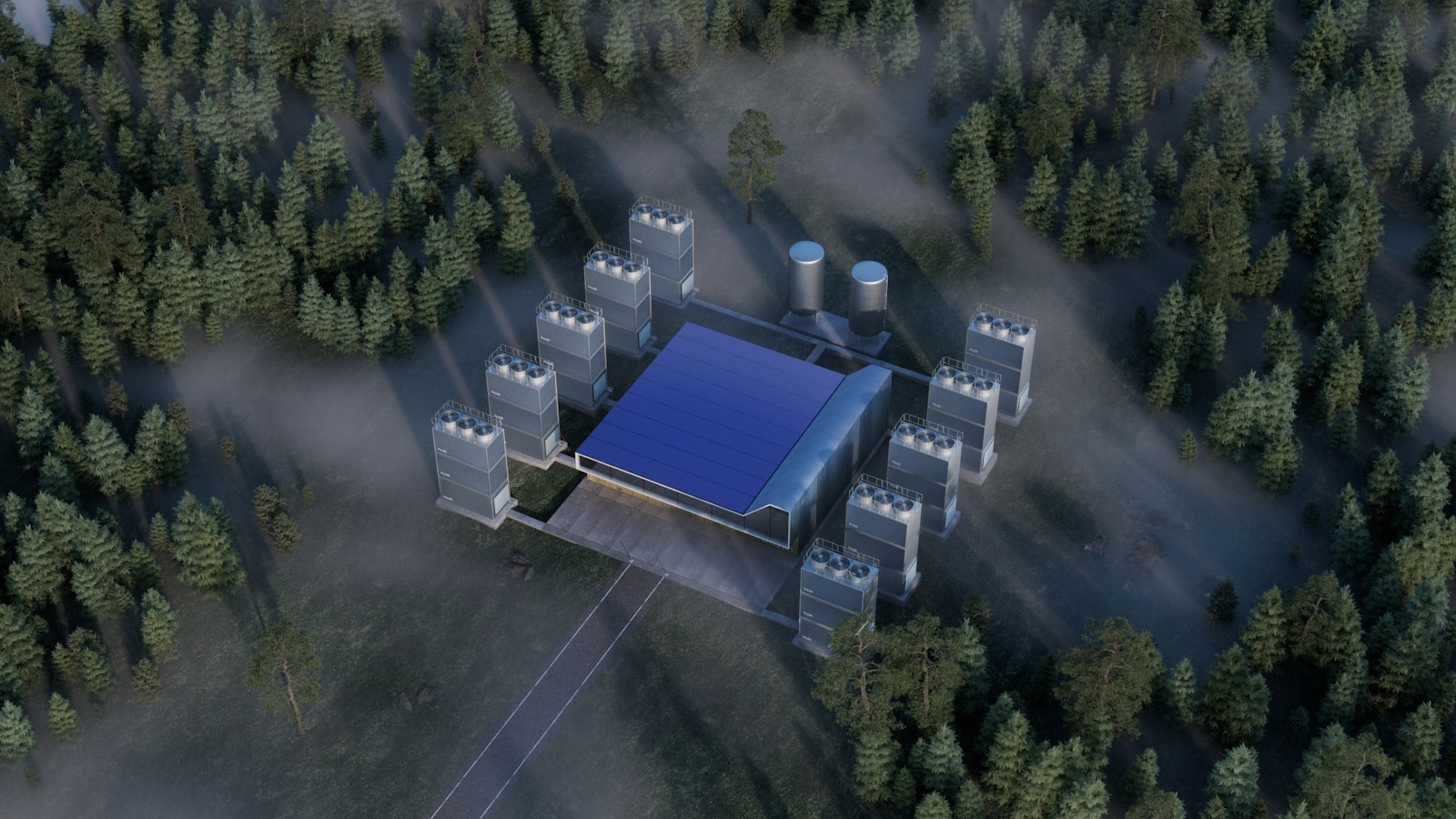

Using superstructure optimisation – which involves advanced modelling techniques – a broad selection of configurations were tested with the goal of identifying the most cost-effective design capable of capturing 10,000 tonnes of CO2 per year. At this scale, the system is directly comparable to other commercially viable processes.

‘Recycling carbon in this way is a powerful idea, with potential to create many new value chains and enable energy independence by embedding renewable energy into the production of conventional fuels and chemicals,’ added Dr Melis Duyar, Associate Professor in Chemical and Process Engineering at the University of Surrey.

You can read the full paper here.

Earlier this week, Environment Journal reported on the fact more than 50% of decarbonisation technologies the UK is reliant on for its net zero roadmap remain at an ‘unmatured’ stage. This means they have not been proven to work cost-effectively at the scale necessary to achieve climate goals.

Image: PHLAIR / Unsplash

More on energy and net zero:

Over half of UK decarbonisation plans still dependent on unmatured tech

Triple Point selected to deliver UK Government Green Heat Network

Local authorities ranked by ‘energy crisis hotspots’ as price cap rises